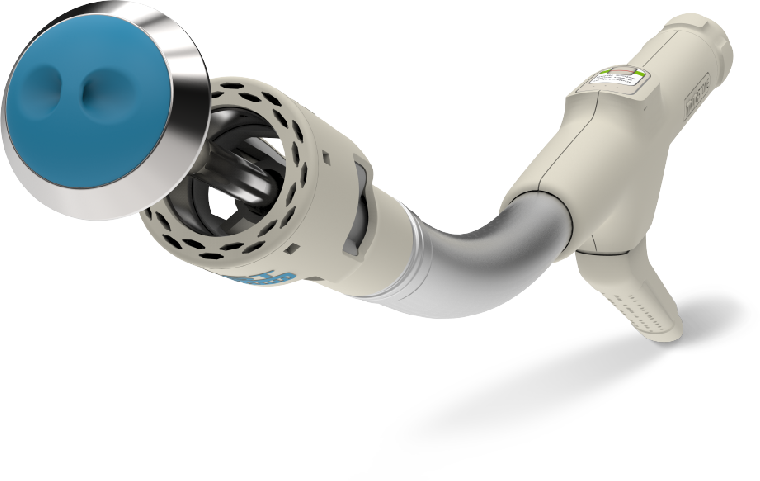

The award-winning Circular Stapler (CST) has 200% more housing capacity compared to standard staplers. The CST’s increased housing capacity improves staple line formation by allowing the tissue to lie flat between the anvil and the cartridge which then does not subject it to unwanted compression during firing (also known as the piston effect).

THE

CST CIRCULAR

STAPLER

Circular staplers were first created in 1978, but for more than 40 years there had been little innovation upon the original design.

FEATURES AND BENEFITS

OF THE CST

WHAT SETS US APART

LARGER HOUSING VOLUME

& COMPRESSION-FREE FIRING

The CST’s 200% larger housing combined with its compression-free firing mechanism is setting new standards in circular stapling technology and providing precision without the need for power.

Standard

Circular stapler

Smaller housing

Resulting in unwanted tissue compression and overflow, often causing crossed staple lines.

Overflow on staple line

Smaller housing may prevent tissue lying flat on the cartridge.

Compressed firing

Unwanted compression of the staple line during firing may cause the tissue to bunch affecting the staple line’s integrity.

Lawmed

CST Stapler

200% larger housing

Allows more tissue to be included in the excision doughnut, minimising the risk of cross staple lines.

Tissue lies flat

Larger housing allows tissue to lie flat on the CST cartridge.

Compression-free firing

Allowing tissue to stay in position on staple line during firing.